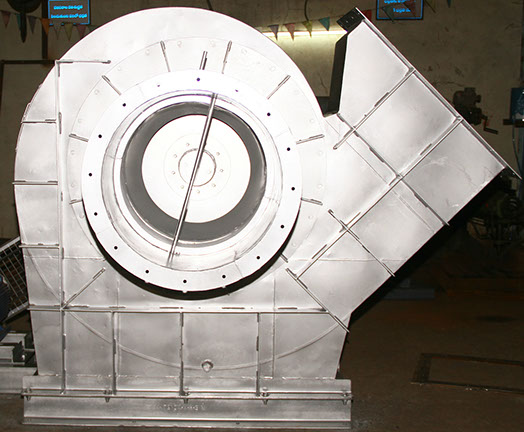

Centifugal fans

A centrifugal fan is a mechanical device for moving air or other gases. These fans increase the speed of air stream with the rotating impellers. They use the kinetic energy of the impellers or the rotating blade to increase the pressure of the air/gas stream which in turn moves them against the resistance caused by ducts, dampers and other components. Centrifugal fans accelerate air radially, changing the direction (typically by 90o) of the airflow. They are sturdy, quiet, reliable, and capable of operating over a wide range of conditions]

Centrifugal fans are constant CFM devices or constant volume devices, meaning that, at a constant fan speed, a centrifugal fan will pump a constant volume of air rather than a constant mass. This means that the air velocity in a system is fixed even though mass flow rate through the fan is not.

The centrifugal fan is one of the most widely used fans. These fans are widely used in the HVAC industry today.It is used in transporting gas or materials and in ventilation system for buildings.[4] They are also used commonly in central heating/cooling systems. They are also well-suited for industrial processes and air pollution control systems.

Centrifugal fan types Impellers.

Forward-curved Impeller.

Forward-curved impellers have blades which curve toward the direction of Rotation. these fans have low space requirements, Low tip speeds & Quite in operation. They usually are used against low to moderate static pressures, such as those encountered in Heating and air conditioning & Ventilation. This type of fans are not recommended for dust (or) Particulate.

Backward-curved / Inclined Impeller.

Backward-curved impeller blades are inclined opposite to the direction of fan rotation, This type usually has higher tip speeds & Provide high fan efficiency & Relatively low noise levels with non-overloading horsepower charracterstics.

Backward curved fans can have a high range of specific speeds but are most often used for medium specific speed applications—high pressure, medium flow applications.

Backward-curved fans are much more energy efficient than radial blade fans and so, for high power applications may be a suitable alternative to the lower cost radial bladed fan. The blade shape is conductive to material build-up so fans in this group should be limited as follows.

a) Single thickness blade : Solid blades allow the unit to handle light dust loading (or) Moisture. it should not be used with particulate that would build up on the under-side of the blade surfaces

b) Airfoil Blade: Air foil Blades offer higher efficiencies and lower noise characteristics. Hollow blades erode more quickly with material and fill with liquid in high humidity applications. These should be limited to clean air service.

Straight radial Impeller.

Radial impellers have blades which are straight or radial from the hub. The housings are designed with their inlets and outlets sized to produce material conveying velocities. The radial blade shape will resist material build-up, this fan design is used for most exhaust system applications when particulate will pass through the fan. but they are often characterized by greater noise output. High speeds, low volumes, and high pressures are common with radial blower and are often used in vacuum cleaners, pneumatic material conveying systems, and similar processes.

1.SISW Fans

2.DIDW Fans

3.Boiler ID Fans

4.Axial flow fans

Types of drive mechanisms:

The fan drive determines the speed of the fan wheel (impeller) and the extent to which this speed can be varied. There are three basic types of fan drives.[5]

Direct drive

The fan wheel can be linked directly to the shaft of an electric motor. This means that the fan wheel speed is identical to the motor's rotational speed. With this type of fan drive mechanism, the fan speed cannot be varied unless the motor speed is adjustable.

Belt drive

A set of sheaves are mounted on the motor shaft and the fan wheel shaft, and a belt transmits the mechanical energy from the motor to the fan.

The fan wheel speed depends upon the ratio of the diameter of the motor sheave to the diameter of the fan wheel sheave and can be obtained from this equation:[5]

Fan dampers and Vanes.

Fan dampers are used to control gas flow into and out of the centrifugal fan. They may be installed on the inlet side or on the outlet side of the fan, or both. Dampers on the inlet side (inlet vanes) are designed to control gas flow by changing the amount of gas or air admitted to the fan inlet.

Global Envro AIR Systems(P)LTD

Global Technologies

Global Metallurgicals

Global Impex

Global Enviro Group Companies